Fire prevention, along with active and passive firestop protection in building construction, is a critical consideration for those having responsibility for the design, construction, or refurbishment of new and existing buildings. This is specifically relevant when considering the diversity of building types, and this is generally described as the ‘built environment.’ Too often, the difference between a safe environment and a deadly one is only a few minutes if adequate fire protection measures have not been considered.

Controlling the Development of Fire through Design Measures

How a fire develops is totally dependent on how it is controlled. Design measures are taken to influence the formation and spread of fire, smoke, and toxic gasses throughout the built environment, typically adopting a balanced approach.

Detection, suppression, and containment are fundamental principles utilized to make built environments fire-safe, thus covering the safety of the occupants, firefighters, contents, and buildings in the surrounding vicinity; essentially, the objective is to ‘gain time.’

Compartmentation is a globally applied practice for fire safety and forms the fundamental principle of containment, and the purpose is to contain the fire in its area of origin for as long as possible by dividing the structure into ‘manageable’ fire cells/zones or compartments. These fire cells are divided by means of fire-resistant rated wall or floor/ceiling assemblies and must be rated against the location and criteria. There are five areas of application which need to be considered.

Understanding Service Penetrations and Firestopping in Buildings

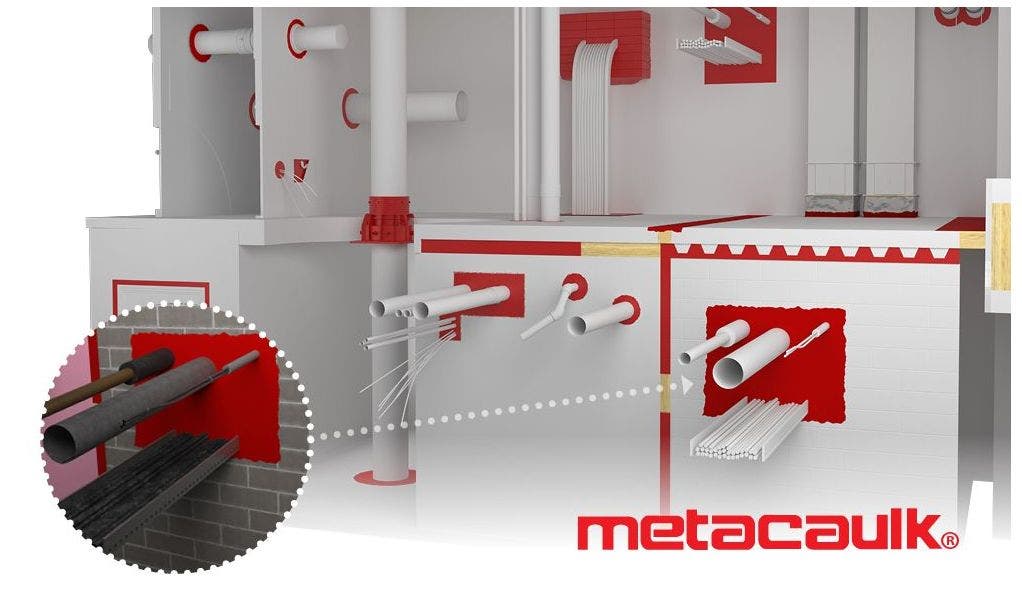

Service penetrations, also known as a through penetration, is a void or opening created in a fire-rated assembly that allows for a ‘service’ to pass through. By necessity, a building needs services to function; electricity, water, heating, and ventilation are standard utilities that can be found in any structure. When these ‘services’ pass through a fire-rated assembly, it can compromise the original integrity and therefore require sealing or firestopping.

Membrane or partial penetration is an opening made in one side of the fire-rated assembly.

A construction joint is an assembly designed to absorb the heat-induced expansion and contraction of construction materials safely; it also absorbs vibration and allows movement due to ground settlement, thermal expansion, or earthquakes.

Linear gaps seals or perimeter fire barriers are voids created at the intersection of exterior curtain wall assemblies and fire-rated floor or floor-ceiling assemblies.

The Importance of Cavity Barriers in Fire Protection

Cavity barriers are usually considered as the space between two fire-rated assemblies. This is often between two ’skins‘ separated by a hollow space (cavity). The skins can be either masonry brick / concrete block or drywall systems. These are designed to divide large spaces into manageable areas of risk, typically to continue a compartment wall up to the roof or to the underside of the floor.

RectorSeal's Comprehensive Range of Firestopping Solutions for Various Building Structures

RectorSeal has developed a fully tested and compliant range of firestopping products covering the vast majority of applications and design criteria for even the most complex structures. Metacaulk firestopping products from RectorSeal conform to ASTM E814 (UL 1479), ASTM E1966 (UL 2079), and CAN/ULC-S115 test standards.

In summary, we could generalize that there are two distinct groups of fireproofing products that are used, those that are suitable for non-combustible penetrants, such as metallic pipes, air ducts, conduits, trunking, busbars or construction/ linear joint, and those products which are suitable for combustible penetrants, such as ‘plastic’ pipes, insulated pipes/ducts and single or bunched cables.

Maintaining Fire System Integrity in Non-Combustible Applications with Metacaulk 1200

With the noncombustible application, the main issue is movement during service life or in a fire, which could disrupt the fire system allowing a passage to form for fire, smoke, and toxic gasses to pass through. A typical solution for this application type is an elastomeric seal. Metacaulk 1200 is a “one” component water-based, highly elastomeric firestop sealant designed to maintain the system's integrity and allow for the expected movement. It has been formulated for both caulk and spray grade applications, exhibits excellent non-sag characteristics, and will help maintain a structure's sound reduction index. It is easy to apply and is protected in a wet and dry stage against mold growth.

Preventing Fire Spread through Combustible Penetrations with Metacaulk 1000 and Firestop Joint Strip

For combustible applications, whether it be a plastic pipe, combustible insulation, or cable assignment, the issue is that the penetrant will burn/melt, leaving a void for fire, smoke, and toxic gasses to pass through. The solution for this type of application would be a pressure-based intumescent product that will expand at the same rate as the melting penetrant to form a foam char, thus preventing the passage of fire, smoke, and toxic gasses. Metacaulk 1000 is a pressure-exerting intumescent sealant that is suitable for sealing a wide range of combustible service penetration in both vertical and horizontal applications. Alternatively, the Metacaulk® Firestop Joint Strip is a highly intumescent, graphite-based composition on an elastomeric synthetic compound. Similarly designed for both combustible service penetrations and construction joints in a wide range of building materials.

There are many variants to consider when selecting the correct firestop solution, so RectorSeal has developed a fully interactive web-based platform with a system selector that allows designers to easily determine the most suitable and appropriate system for the application.

To find out more, visit https://rs.today/metacaulk

Please visit www.rectorseal.com for additional details, and follow us on LinkedIn, Facebook, YouTube, Instagram, and Twitter for the latest product enhancements and news.