Why Flexible Pipe Might Be a Solution for Your Next Water Heater Installation

When installing or replacing a tanked or tankless water heater, it is common practice to use flexible pipe connections to the primary water source entering and exiting the water heater. Flexible pipe connections for tanked and tankless water heaters are economical, proven, easy to install, and recommended when the piping must bend and maneuver in tight spaces.

When it comes to water heating piping connections, there are several options available, including copper, PEX (cross-linked polyethylene), PVC (polyvinyl chloride), and corrugated stainless-steel (CSST).

Comparing Characteristics and Suitability: A Quick Overview

A. Copper piping has long been a popular choice for water heater connections. It is durable, resistant to high temperatures, and offers excellent corrosion resistance. Copper pipes can handle both hot and cold water and have a long lifespan. However, copper can be relatively expensive compared to other materials, and the installation process may require soldering or brazing.

B. Pex piping has gained popularity in recent years due to its flexibility and ease of installation. PEX is a flexible plastic material that can withstand high temperatures and is resistant to corrosion. It can be easily bent and roughed-around obstacles, making installations more straightforward. PEX is also relatively affordable compared to copper. However, some local building codes may have restrictions on use and may not be suitable for all applications or climates.

C. PVC piping is commonly used for cold-water applications but is not recommended for hot water connections to water heaters. PVC can become brittle when exposed to high temperatures, potentially leading to leaks or pipe failure.

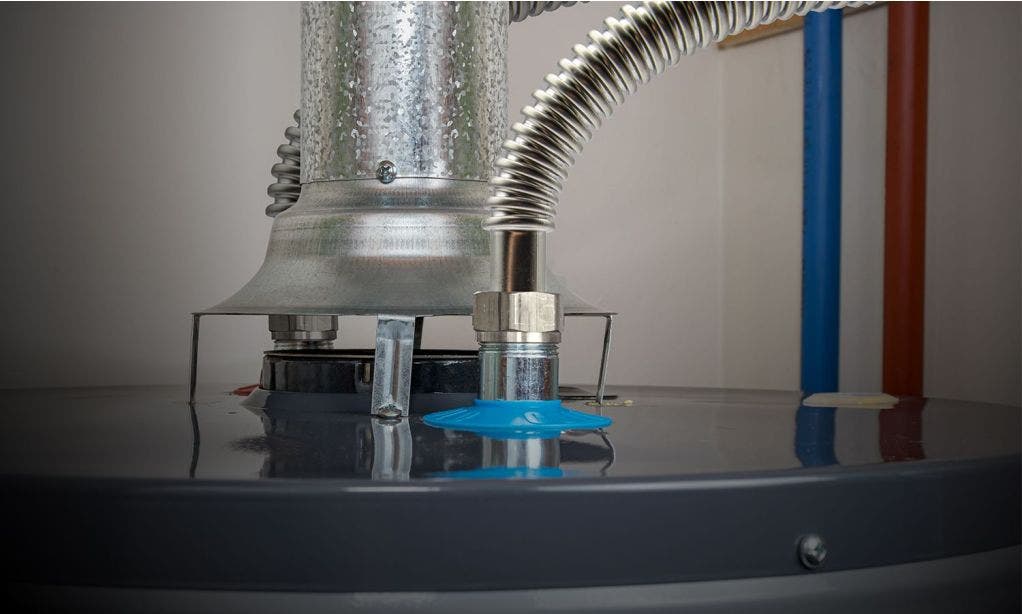

D. Corrugated Stainless-Steel Piping (CSST) offers flexibility, durability, and high-temperature resistance. It is highly resistant to corrosion, eliminating the risk of leaks caused by mineral buildup. Its flexibility allows for easier installation and maneuverability. Additionally, CSST often incorporates safety features such as electrical conductivity, to prevent sparks. Further, the corrugated design of the pipes can help reduce noise and vibration that might exist beyond the piping in the water heater system.

Versatility and Reliability: Corrugated Stainless-Steel Piping for Water Heater Connection

Since its introduction into the U.S. market over 20 years ago, corrugated stainless-steel piping has been installed in single-family homes as well as commercial installations. It’s common to see corrugated stainless-steel piping used in areas prone to seismic activity and where lightning strikes are common. With the ability to withstand environmental disturbances, corrugated stainless-steel piping is a reliable, proven, and safe piping option for tanked and tankless water heater connections. Corrugated stainless-steel pipe can be used for different fuel sources, including natural gas, propane, and even solar water heating systems. Its versatility allows for easy adaptation to various water heating systems, making it a suitable choice for a variety of residential and business installations.

Regardless of the piping material, there are some basics to consider when installing or connecting a water heater using flexible pipes.

1. Compatibility: Some water heaters require specific types of piping, and using the wrong type can lead to leaks or other related problems.

2. Durability: Tanked and tankless water heaters can generate a lot of heat. Choose flexible pipes that are durable and designed for high-temperature use without degrading or melting over time.

3. Size: Confirm the flow rate needed to support the water heater and select matching piping. Using a pipe that is too small can cause restrictions in water flow, while a pipe that is too large can lead to wasted energy and additional inefficiencies.

4. Installation: Flexible pipes should always be installed according to the manufacturer’s recommendations and suitable to meet any local, regional, or national codes. To help prevent potential leaks, the installation may often involve using proper fittings, clamps, and connectors to secure the pipe and support its function.